ball end mill feeds and speeds

Radial Side Depth of Cut. Tools in-stock typically ship same day when ordered by 600PM EST.

Cnc Feeds And Speeds A Starting Point Myers Woodshop

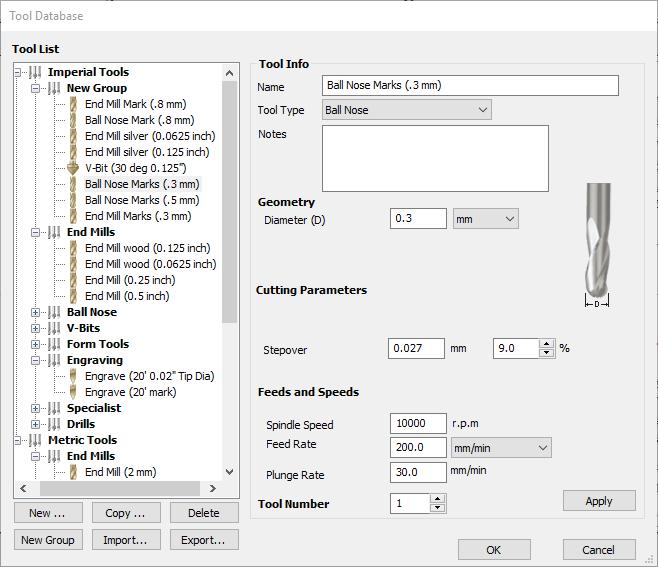

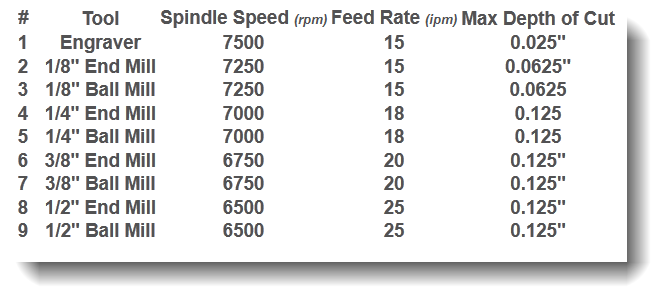

End Mill Speed Feed Calculator.

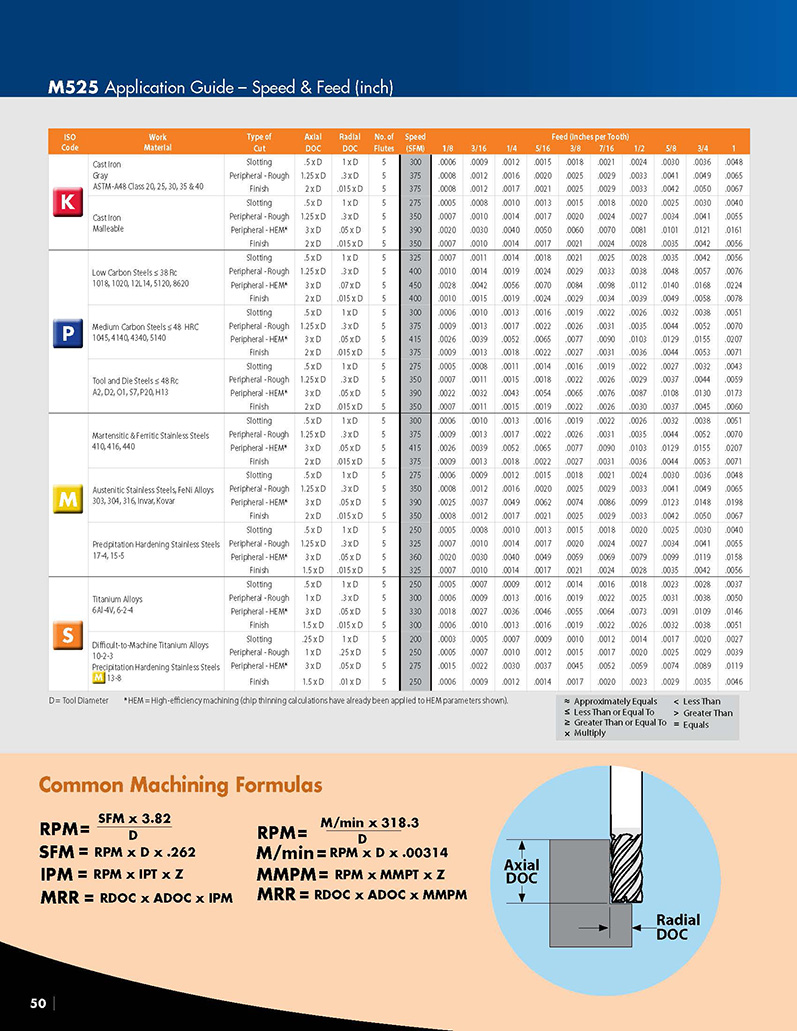

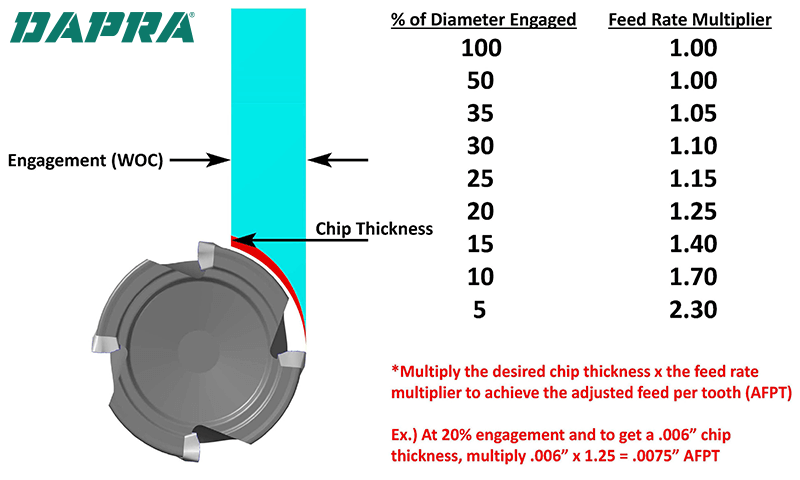

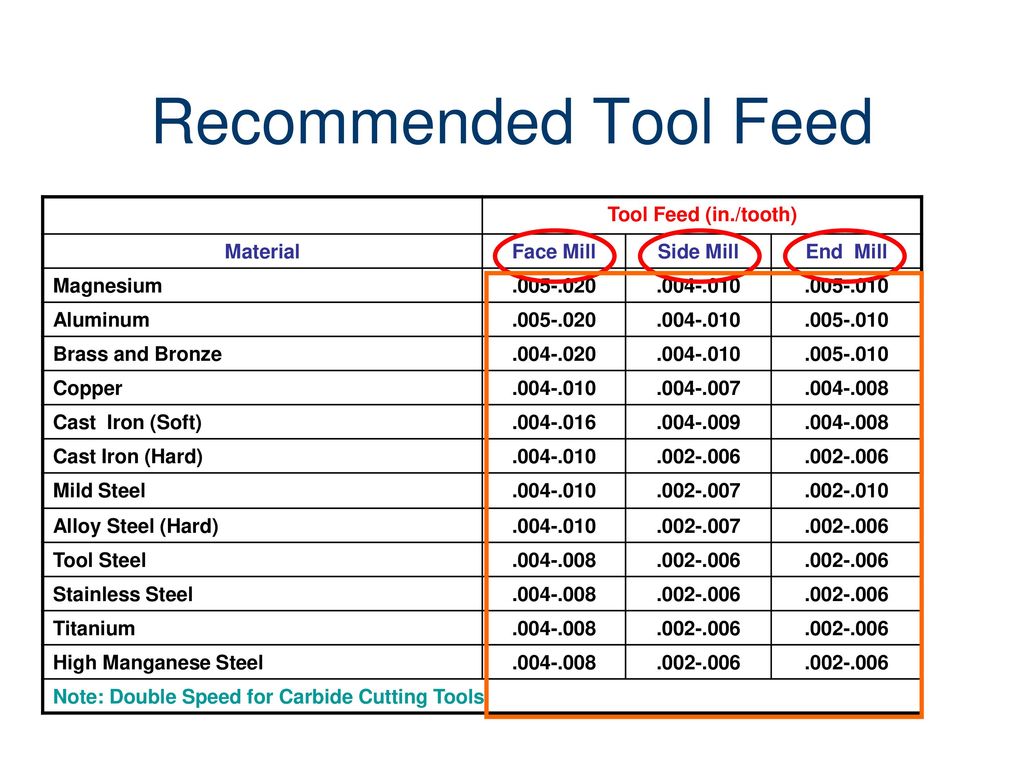

. The Adjusted Feedrate Chip Thinning Ball End Mill Effective Diameter Calculators are available in the tabs above. Speeds and feeds speeds and feeds for key cutters material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15 41l30-41l50 4140-4150 4140 35 hrc. Do not use flood coolant with hard mills.

For assistance setting up your milling program contact a Dapra applications specialist or call 800 243-3344. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes. SFM 08 X Highest Speed Range.

Recommended Cutting SpeedsFeeds Recommended Cutting Speeds for Dapra Ball Nose Cutters MATERIAL GROUP EXAMPLE F1T1 uncoated FPO FP-GLH FP-HMTS PCD Geometry FPT PLAIN STEELS 3C 1008 1018 12L14 300-600 700-1100 800-1200 800-1200 NR HBN RDBN N002-007 3-6C 1040 1045 1055 5-15C 1060 1070 1095 ALLOY STEELS Mo 4012 4320 4340. Because the tip is the weakest most fragile portion of the tapered end mill. SMM SFM X 3048.

- The maximum feed for roughing is the high rate - The starting feed for the best finish is the low rate - The starting feed for roughing should be taken from the middle of the feed range Formulas. Ball Nose Finishing Mills Speed Feed Calculator Instructions. Speeds and Feeds Master Library of Harvey Tools entire tool line up of Specialty End Mills Drills and Cutting Tools.

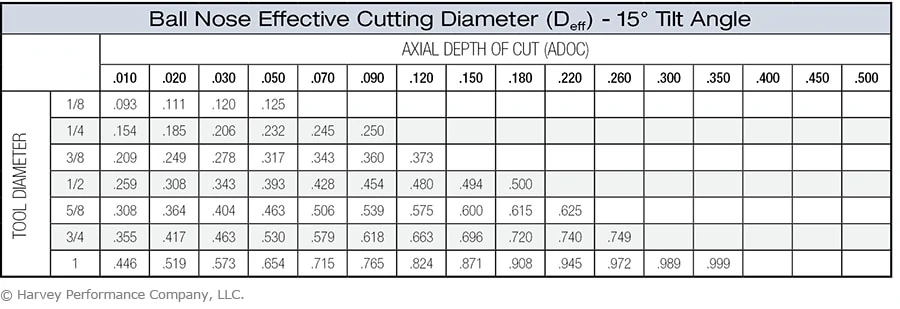

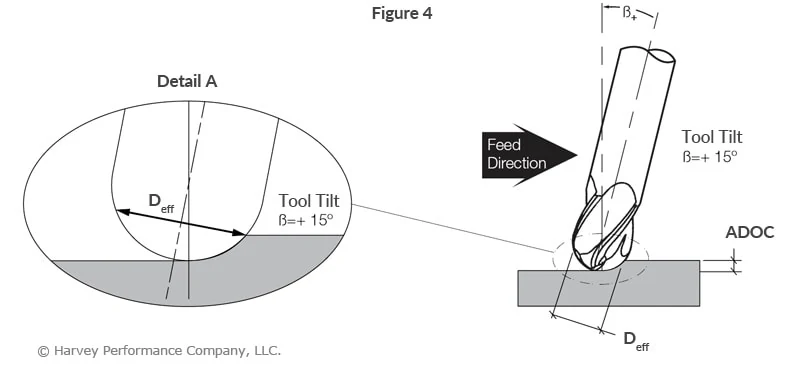

04-25-2016 0428 PM 2 Bigbore050 Aluminum Join Date Apr 2016 Country UNITED STATES StateProvince Missouri Posts 109. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. Performance of hard mills is dictated by heat evacuating in the chips.

Ftmin use a plunge rate of. I ran the same cutter on a mill-turn machine engraving the same 17-4 at 5000 RPM and 5 IPM 005 DOC and plunge in. Then decrease speed by 10.

Mild - 1018 2-3 Carbon 350 0006016mm 0011028mm 0017043mm 002051mm. Ad The Best Solid Carbide tools - Quick Delivery. High Feed milling of Steel and Cast Iron 30Rc - 60Rc.

Profiling Cutting Depth Recommendations and Adjustments Axial Depth of Cut AD Axial Depth of Cut 15 X Tool Dia. Feeds - IPT inchestooth and MMPT mmtooth Material. This will adjust the feedrate if less than the tool rad.

Upcut Ball End Mill 13636 77-102 1 x D 003-005 2 18-30 18000 1-14 Carbide Tipped Surfacing Cutter 13555 91-000 12-34 x D 2 200-600 12000-16000. Ad Discover Products by Brand Type Size. All this is done on a lathe.

Surface speed π 1 12 π 1 12 Tool Diameter Answer rpm Feed rate Feed Rate Spindle Speed RPM Number of Flutes Chip Load inches Spindle Speed Number of flutes Chip Load Answer inchesmin Plunge rate Use a plunge rate of 50 or less of the feed rate. FINE PITCH EXTENDED. End Mill Speeds And Feeds Chart - Uncoated Carbide.

Feed should be 05 X Suggested Value. Fill in the blocks shaded in blue with your application information. From the chart chip thickness is 0005 and all of our ball nose finishers have 2 flutes.

Your FEEDRATE inches per minute can be calculated by the formula. The radial DOC is 05 axial increase from 05 to 25 3000 rpm at 002 Feed per tooth 3 flute SC 5 ball endmill brand new. 3 FLUTE EXTENDED NECK ROUGHING.

When I worked at a very popular and prominent medical manufacturer we engraved text in 17-4 PH all day long with a 132 ball end mill at 15000 RPM and 5 IPM 005 DOC on a horizontal machining center and we plunged in. High Feed milling of Steel and Cast Iron 30Rc - 60Rc. Ball Nose Milling Without a Tilt Angle.

Includes miniature Square Ball and Corner Radius and Tapered end mills in a variety of diameters lengths of cut and overall reaches. Adjust speedsfeeds and width of cut to pull enough heat in chip. Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End.

Use Higher SFM Range. I also thought about throwing the part on a cnc mill and run a second op. Using the same criteria as the spindle speed calculation RPM 6037.

SFM and Feed For Radial Depth of Cut use 025 X Tool Dia. Calculate De Effective Cutting Diameter. For Long and Extra Carbide Reduce Feed by 50.

So for a feed rate of. 3 FLUTE EXTENDED NECK FINISHING. 3 FLUTE BALL NOSE.

Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs. RPM x chip thickness x of flutes. 5 FLUTE 45 HELIX.

Ie- 6037 x 0005 x 2 6037 IPM. HOW TO CALCULATE TAPERED END MILL INCHES PER MINUTE FEED. PREMIUM CARBIDE MILL SPEED FEED 4-F1ute - Ball Nose End Mills CHARTS Aluminum Alloys Carbon Steels Alloy Steels Tool Steels 285-275 Bhn Cast Iron RPM 7300 4900 3600 2900 2400 1800 1430 1200 1000 920 810 730 O3D Material Hardness Diameter 332 18 532 316 14 516 38 12 916 58 1116 1316 Carbon Steels.

Ships and Delivers Fast. The calculator will automatically provide the necessary speed and feed in the green fields. Recommended RPM range is 1070 - 2292 RPM At the speed of 1681 RPM the recommended feed rate is 504 - 2017 IPM Interpreting Results.

Ad Single End and Double End Cobalt Long Metric Miniature Roughing. High Speed Chatter Free Machining of Most Steel Alloys Under 40Rc. RPM x Suggested chip load of the smallest tip diameter x of flutes INCHES PER MINUTE FEED 85 OF TAPERED END MILLS UTILIzE 3 FLUTE DESIgN375 DIAMETER250 DIAMETER Tapered End Mills.

A Practical Approach To Identify Feeds And Speeds Settings For Peak And Stable High Speed Machining Performance

Viper Dvh Speeds Feeds Destiny Tool

Inch End Mill Speed Feed Micro 100 Pdf Catalogs Technical Documentation Brochure

Common Formulas For Milling Operations Speed Feed Sfm Ipt Mrr Dapra Corporation

Bcb Series Aluminum Ball End Mills Cid Performance Tools

Speed And Feeds For High Speed Steel And Cobalt End Mills

Micro End Mills 0 2mm 0 5mm Feed Speed Nomad Carbide 3d Community Site

Understanding Cnc Cutting Tool Speeds Feeds Destiny Tool

Conical Tool Speed Feeds Tapered End Mills Cutting Tools

Ball Nose Milling Strategy Guide In The Loupe

Specification General Purpose End Mill

Raptor Dvh Speeds Feeds Destiny Tool

Dynamic Spindle Speed And Feed Rate For Ball End Mill 3d Finishing Autodesk Community

Speeds And Feeds Speeds And Feeds Cim Product Development Ppt Video Online Download

Ball Nose Milling Strategy Guide In The Loupe

What Speeds And Feeds Do I Use On Wax Or Renshape Chris And Jim Cim